качать документы: Номенклатурный прайс лист по ЗИПу насосов НЦВ (Excel, 166kb) Анкетные данные дилера ООО «Завод Молот-Механика»(Doc, 37kb) Бланк заявки на поставку ЗИПа судовых насосов (Doc, 53kb) Предложение ООО «Завод Молот-Механика» по судовым насосам (Doc, 171kb) Типовой Дилерский договор ООО «Завод Молот-Механика» по НЦВ (Doc, 73kb) SDEP (ВНЭП)  Submersible drainage centrifugal electric pump units SDEP100/20 and SDEP100/30. Submersible drainage centrifugal electric pump units SDEP100/20 (SDEP100/30) are made under specifications ТУ У 29.1-03327760-004-2005 (АЭТА 062313.004ТУ) and are intended for pumping out of sea and fresh water polluted by refinery waste with temperature of not above than 70°C from the flooded premises of tankers. Pumped out sea water can contain impurity of water polluted by mineral oil and have temperature up to 70°C. In emergency or contingency it can be used as an aid of water supply or water-outflow. Table 1. Technical specifications.

Submersible drainage centrifugal electric pump units SDEP100/20 and SDEP100/30. Submersible drainage centrifugal electric pump units SDEP100/20 (SDEP100/30) are made under specifications ТУ У 29.1-03327760-004-2005 (АЭТА 062313.004ТУ) and are intended for pumping out of sea and fresh water polluted by refinery waste with temperature of not above than 70°C from the flooded premises of tankers. Pumped out sea water can contain impurity of water polluted by mineral oil and have temperature up to 70°C. In emergency or contingency it can be used as an aid of water supply or water-outflow. Table 1. Technical specifications.

|

Performance data |

SDEP 100/20 |

SDEP 100/30 |

| Delivery, m3/hour |

100 |

100 |

| Head, m |

20 |

30 |

| Minimal thrust, m |

1,0 |

1,0 |

| Motor power, kW |

11,7 |

16 |

| Rated operational current, A , at network pressure of 380 |

25,2 |

32 |

| Rated operational current, A , at network pressure of 220 |

43 |

55 |

| Power frequency, Hz |

50 |

50 |

| Sort of current |

three-phase alternating current |

three-phase alternating current |

Values of key parameters are specified at work of the pump on water with the temperature of 293K (20°C). Norms of pump parameters in table 1 are shown for a nominal rating. Characteristics Standard specifications of SDEP 100/30 pumps tested on water with density of 1000 kg/m3 at synchronous frequency of rotation n=3000 rev/min are presented on fig. 1 and fig. 2.  Symbols: Q – pump delivery; H – pump head N – pump capacity; n – efficiency of the pump Complete set of delivery Completeness of delivery is stipulated by the contract. The typical complete set of delivery of pumps in usual version contains of: • pump with electric motor and start-up equipment; • operational and accompanying documents (pump passport, configuration and operational manual). Under a separate contract the delivery of additional components is possible: on installed length from the unit up to the stator – a submersible oil and gasoline proof cable, (length 35m); on installed length from the stator to the onboard power source – a flexible oil and gasoline proof cable( 151 m). • water horse to the pump • carriage for transportation; • complete repair set of spare parts (it is recommended for repair of three pumps); • certificate of the Registry of Shipping (delivery only to sea crafts supervised by the Registry). Design features The pump consists of one-stage centrifugal pump and a special electric motor of alternating current. A driving wheel of the pump is forced on the console end of a shaft of the electric motor. The internal cavity of the electric motor with a stator winding and a rotor should be filled with working liquid (for example, distilled water). Cooling of the pump is carried out by pumped over water. For pumping over sea water the details of the pump are made of bronze and stainless steel. In order to prevent premature corrosion of pumps by fresh water it is necessary to establish the pump so that during inactivity it has no constant contact with pumped out water. After installation of electropump unit in a place of its regular arrangement it is preferable to store it in vertical position with a cavity of stator filled with working liquid, horizontal arrangement of the electropump unit is allowed – in this case the cavities of the stator are filled with working liquid directly before operation. Unit design description

Symbols: Q – pump delivery; H – pump head N – pump capacity; n – efficiency of the pump Complete set of delivery Completeness of delivery is stipulated by the contract. The typical complete set of delivery of pumps in usual version contains of: • pump with electric motor and start-up equipment; • operational and accompanying documents (pump passport, configuration and operational manual). Under a separate contract the delivery of additional components is possible: on installed length from the unit up to the stator – a submersible oil and gasoline proof cable, (length 35m); on installed length from the stator to the onboard power source – a flexible oil and gasoline proof cable( 151 m). • water horse to the pump • carriage for transportation; • complete repair set of spare parts (it is recommended for repair of three pumps); • certificate of the Registry of Shipping (delivery only to sea crafts supervised by the Registry). Design features The pump consists of one-stage centrifugal pump and a special electric motor of alternating current. A driving wheel of the pump is forced on the console end of a shaft of the electric motor. The internal cavity of the electric motor with a stator winding and a rotor should be filled with working liquid (for example, distilled water). Cooling of the pump is carried out by pumped over water. For pumping over sea water the details of the pump are made of bronze and stainless steel. In order to prevent premature corrosion of pumps by fresh water it is necessary to establish the pump so that during inactivity it has no constant contact with pumped out water. After installation of electropump unit in a place of its regular arrangement it is preferable to store it in vertical position with a cavity of stator filled with working liquid, horizontal arrangement of the electropump unit is allowed – in this case the cavities of the stator are filled with working liquid directly before operation. Unit design description

для увеличения нажмите на картинку

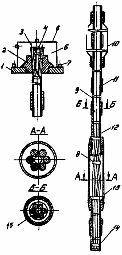

A submersible drainage electropump SDEP(fig. Б2) is a single-block unit consisting of one-stage centrifugal pump and an electric motor. A steel case of the electropump 20 which simultaneously acts as a rose is put on the electric motor. During operation water gets into the pump, passes along the case of the electric motor and cools it. Rotation of a shaft of the electropump goes on clockwise. The electric motor consists of a stator and a rotor. Active parts of the rotor 2 and the stator 3 are made from electric steel sheets. The winding of the stator 7 is fulfilled with special waterproof copper wire with polymeric isolation; the case of the stator 4 is made of steel. A current-carrying cable 12 joins to conductors of the winding. At an end face of the top cover a terminal for connection of a ground wire is stipulated. The rotor of the electric motor has a short-circuited winding from copper rods (a squirrel cage). In bearing boards 5.,6 the bearing bushes 9 are pressed in which together with bearing plugs 8 and basic heels10 on a shaft 1of the electric motor form radial and thrust bearings. The condensing rubber rings 41 which protect the electric motor from penetration of sea water are laid in annular grooves on centering spigots of boards. The transport eye 11 is welded on the bottom 18, in the end face of the bottom there are two steel fuses 19 condensed by rubber rings 42 both intended for pouring and draining of working fluid from the electric motor. The pump part of the unit is mounted on the face part of the electric motor and connected to it with an admission 24 by means of stud bolt 16. In supply there is an aperture for current-carrying cable sealed by a stuffing box 13 with a packing nut 14. A pump impeller 26 is forced on the free end of the motor shaft on a key 37 and is fixed by nuts. For unloading of thrust bearing of electric motor from the axial thrusts, in a nave of the pump impeller there are discharge openings and a seal 27 on the inlet side of the wheel is stipulated. A vaned tapping 25 is attached to the admission by means of stud bolts 30, to which the nipple 34 with a pressure head hose is fastened by means of link bolts 32 . Lip seals 38 warn penetration of sea water inside the electric motor Portable submersible centrifugal electric pump units PSEP (ЭСН) Portable submersible centrifugal electric pump units are made under specifications ТУ У29.1.-033 27760-018:2008 (АЭТА 062313.018ТУ) and are intended for pumping of cold salty and fresh water with the temperature up to 30°C from hard-to-reach ship premises during rescue and ship-lifting operations. Units are made in climatic modification M5 in accordance with GOST 15150. 1.Structure of symbolic notation of units: Pump unit PSEP16/Х – М5 Type of climatic modification in accordance with GOST 15150 Version of pump I – 220 V, II – 380 V Notional index of the unit Electric Sanitary Pump Unit 2. Basic technical specifications of the unit

| Parameter | PSEP-16/II | PSEP-16/I |

| Delivery, m3/h | 30 | 30 |

| Head, m | 20 | 20 |

| Minimum backing-up, m | 6 | 6 |

| Motor power, kW | 4,5 | 4,5 |

| Rated output, kW | 3,6 | 3,6 |

| Rotation speed., r.p.m. | 2870 | 2870 |

| Rated voltage, V | 380 | 220 |

| Rated current of electric motor , А | 8,2 | 14,4 |

| Ratio of starting current to rated current | 6,0 | 6,0 |

| Current frequency, Hz | 50 | 50 |

| Sort of current | three-phase alternating current | three-phase alternating current |

| Phase winding coupling | Star | Delta |

| Dry pump weight without delivery hose and cable, kg | 68,5 | 68,5 |

| Mean life,h | 5000 | 5000 |

| Mean lifetime, y | 10 | 10 |

3. Outline drawing of the units  4. Specifications of PSEP-16 Characteristics of the electric pump unit PSEP-16 tested on water in density of p=961; n=1000 kg/m3, n=2870 r.p.m. 5. Completeness. The complete set of delivery of the unit consists of the following: a unit and start-up equipment; a cable -35m ; according to special order the length of the cable delivered with the unit can be increased. A passport combined with a manual for installation and operation; a logbook; acertificate of necessary classification society (depending on the order). Armature to the electropump unit is delivered under the separate contract. A single complete set of spare parts and accessories is delivered under the separate contract. Under conditions of the contract the unit can be completed with the carriage with the actuator established on it and a cable connecting the unit with the actuator, and also a current carrying cable from the actuator to an onboard network of a vessel. 6. Manufacturer’s guarantees. The Manufacturer guarantees conformity of units to requirements of the present specifications if the consumer adheres conditions of transportation, storage, installation, set up and operation mentioned in the present specifications and operational documentation. Warranty period of the units – 12 months from the date of commissioning, but no more than 24 months from the date of manufacturing. The guarantee is valid in case intact guarantee seals, passports, filled logbook of a product and registry of operation are present. Vertical centrifugal electric pumps VCEP The monoblock one-stage units intended for pumping of sea water with the temperature up to 35°Cand fresh water with the temperature up to 70°CThe stator part of the pump is made from bronze steady against sea water and its vapors. 1.Structure of symbolic notation of units: Vertical centrifugal electric pumps – VCEP Delivery under the tab. 5m3/h – XXX/XXX Head under the tab. 5m – A Symbolic notation of embodiment –X Symbolic notation of casing execution (tab.1)– X Symbolic notation of operating voltage execution (tab.2) – X Starter (*tab.3) – X Temperature of environment (tab.4) – ТУ Technical specifications of delivery 2.Basic specifications of units

4. Specifications of PSEP-16 Characteristics of the electric pump unit PSEP-16 tested on water in density of p=961; n=1000 kg/m3, n=2870 r.p.m. 5. Completeness. The complete set of delivery of the unit consists of the following: a unit and start-up equipment; a cable -35m ; according to special order the length of the cable delivered with the unit can be increased. A passport combined with a manual for installation and operation; a logbook; acertificate of necessary classification society (depending on the order). Armature to the electropump unit is delivered under the separate contract. A single complete set of spare parts and accessories is delivered under the separate contract. Under conditions of the contract the unit can be completed with the carriage with the actuator established on it and a cable connecting the unit with the actuator, and also a current carrying cable from the actuator to an onboard network of a vessel. 6. Manufacturer’s guarantees. The Manufacturer guarantees conformity of units to requirements of the present specifications if the consumer adheres conditions of transportation, storage, installation, set up and operation mentioned in the present specifications and operational documentation. Warranty period of the units – 12 months from the date of commissioning, but no more than 24 months from the date of manufacturing. The guarantee is valid in case intact guarantee seals, passports, filled logbook of a product and registry of operation are present. Vertical centrifugal electric pumps VCEP The monoblock one-stage units intended for pumping of sea water with the temperature up to 35°Cand fresh water with the temperature up to 70°CThe stator part of the pump is made from bronze steady against sea water and its vapors. 1.Structure of symbolic notation of units: Vertical centrifugal electric pumps – VCEP Delivery under the tab. 5m3/h – XXX/XXX Head under the tab. 5m – A Symbolic notation of embodiment –X Symbolic notation of casing execution (tab.1)– X Symbolic notation of operating voltage execution (tab.2) – X Starter (*tab.3) – X Temperature of environment (tab.4) – ТУ Technical specifications of delivery 2.Basic specifications of units

| Specification | VCEP 100/80 | VCEP 100/100 |

| Delivery, m3/h | 100 | 100 |

| Head, m | 80 | 100 |

| Efficiency | 65 | 65 |

| Motor power, kW | 35 | 43 |

| Rotation speed., r.p.m. | 3000 | 3000 |

| Rated voltage,V | 380 | 380 |

| Pump weight, kg | 435 | 520 |

| Mean time between failures, h | 6000 | 6000 |

| Retirement life, h | 50000 | 50000 |

| Lifetime, y | 15 | 15 |

Major units 1,4- seal rings,2- lock washers, 3- impeller, 6,10,11- stuffing box seal, 7- lamp, 8- electric motor, 9- protecting bush, 12- removable cover, 13- pump casing, 14- axis screw, 15- foot pipe.